spray drying temperature

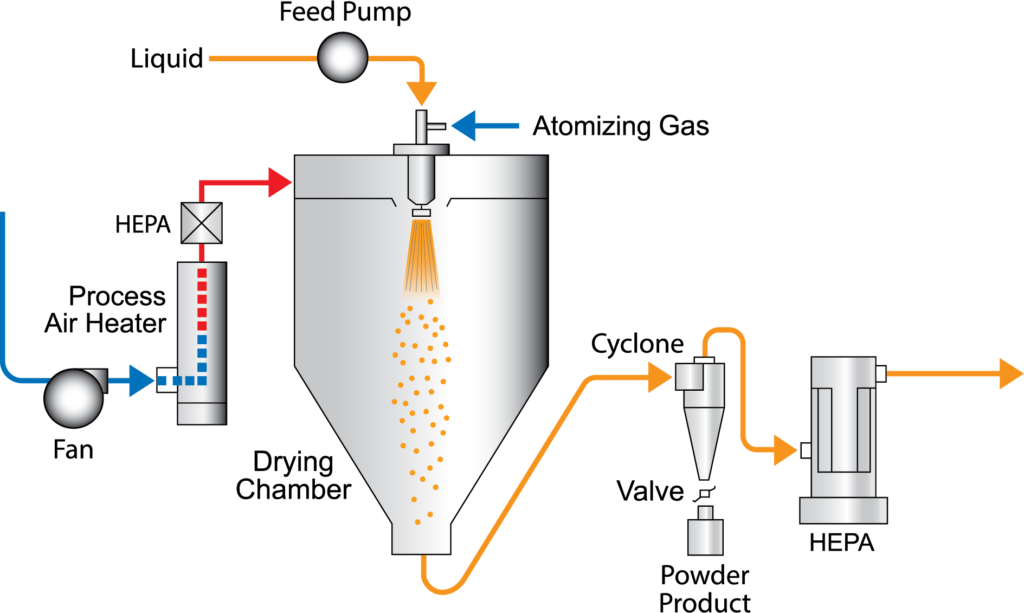

Spray drying is a widely used commercial drying process for products such as tea powdered milk instant coffee and vitamins 1 2The low product temperature and short drying time allow the spray-drying method to be used to dry products that are highly sensitive to heat and maintain product qualities such as color taste and nutrition For example the process of. Spray drying is the continuous transformation of feed from a fluid state into dried particulate form by spraying the feed into a hot drying medium.

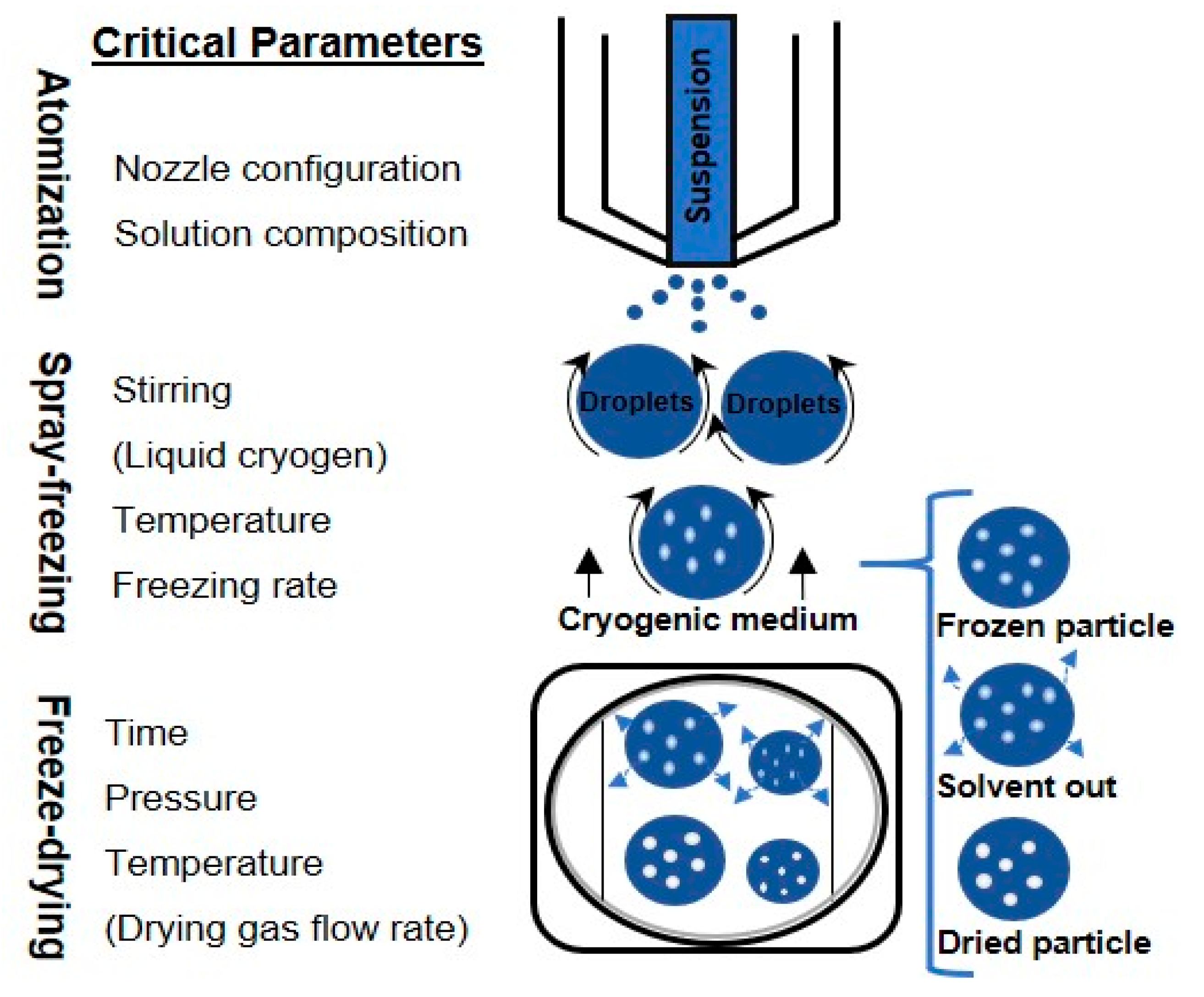

Processes Free Full Text Spray Freeze Drying As A Solution To Continuous Manufacturing Of Pharmaceutical Products In Bulk Html

Spray drying of milk is widely known by people in dairy industry.

. Spray dryers are controlled by programmable logic controllers PLCs or solid-state controllers. Twist Dry TD-HT HIGH-TEMPERATURE SPRAY DRY NOZZLE. This prolongs drying time from approximately 22 sec in a typical single-stage dryer to more than 3 min making it possible to use lower drying temperatures and reduce the heating energy usage by 15 to 20.

Special Spray Dryer For Polyaluminum Chloride. Rated for 7000 psi at 800F. The feed flow rate was 4 mlmin for each experimental trials.

The spray drying parameters were optimized by considering saponin content and foam volume by. End-to-end Spray Drying Solution to Accelerate Your Produce to Market. What is the optimal outlet temperature.

Moisture control is crucial to spray drying. One disadvantage of this laboratory spray dryer is related to the angle of exit of the particles from the. The outlet temperature is a manifestation of the relative humidity in the outlet air.

The influence of temperature could be reduced by using low lipid content in the dispersion ethanolwater mixtures 1090 vv as the dispersion medium addition of carbohydrates 2030 which form a layer around the particles and prevent the. The drying temperature and drying time need close monitoring due to varying levels of humidity present in the inlet air. In the chamber atomized liquid is brought into contact with hot gas usually air at a vacuum resulting in the evaporation of 95 of the water contained in the droplets in a matter of a few seconds.

Spray drying often is used as a method of encapsulation. Optimizing a spray dryers capacity is to increase T by raising the inlet tempera-ture or lowering the outlet temperature. Polyaluminum chloride is an important component in drinking water flocculants.

Paint dry time for metal is typically lower than for other materials. The tower is a one stage spray drying unit which means that the processing time in the spray drying chamber is very short approximately 20 60 s. If the outlet temperature of the second stage drying and the temperature of the drying chamber is low the.

The way in which the spray makes contact with the air in the dryer influences the behavior of the droplet during the drying phase. Therefore if the outlet air temperature is raised the energy efficiency of the unit decreases113435. Utilizes a special body design made from alloy 218 and 303 SS carrier rated for high-temperature applications.

The dropletparticle temperature during an ideal drying process is as follows. Ad Spray Drying Technology for Bioavailability Enhancement Stability More. Thermolabile products pharmaceuticals can be dried at atmospheric pressure and low temperature.

The temperature of the droplet during the whole evaporation process lies between the temperature of the surrounding air. This high-speed centrifugal spray dryer will meet the customers annual output of 10000t polyaluminum chloride drying needs and the material dehydration will be reduced from 433 to 4. Mechanically these dryers are relatively low maintenance units.

There is thus no real equilibrium between air humidity and product humidity. Without considering the high energy consumption spray drying is the most commonly used method because this process reduces the thermal effect on the powder product. Drying air flow rate was 35 m3 h while the its temperature varied from 120 C to 180 C.

Spray drying is a one-step continuous unit operation that employs liquid atomization to produce droplets that are dried to individual particles when moved in a hot gaseous drying medium. Thin coats of spray paint on metal can be dry to the touch after only 10 minutes. Droplets of water having the water activity a w 1 will attain the wet bulb temperature.

Uses metal gaskets no O-ring seals. Freitas and Müller 1998b recommend the use of lipids with melting points 70C eg tribehenin 72C for spray drying. Spray dryer permits high- tonnage production in.

However it can take up to 24 hours. In spray drying systems the exhaust air temperature or humidity provides an input signal that by way of a setpoint will modulate the energy supplied to the process. If the outlet temperature is too low the product particles in the drying chamber.

At the same time the slower more gentle drying process produces more solid particles of improved density and solubility. The feed may be.

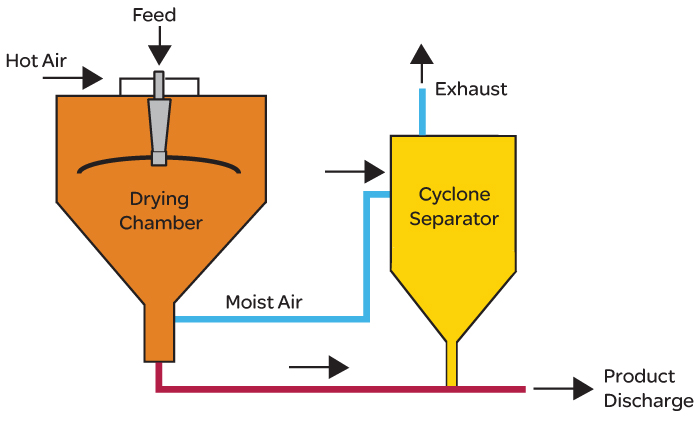

The Spray Drying Process Eurotherm By Schneider Electric

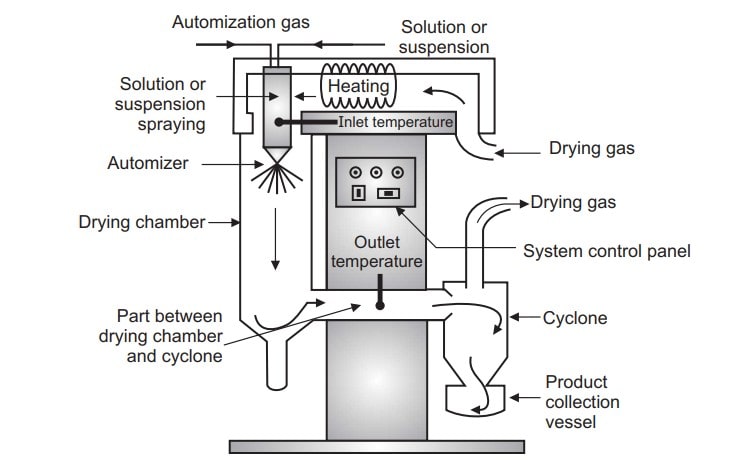

The Schematic Diagram Of The Lab Scale Spray Dryer Download Scientific Diagram

Spray Dryer Principle Construction Working Pharmacy Gyan

What Is The Advantages Of Rotary Dryer Over Spray Dryer

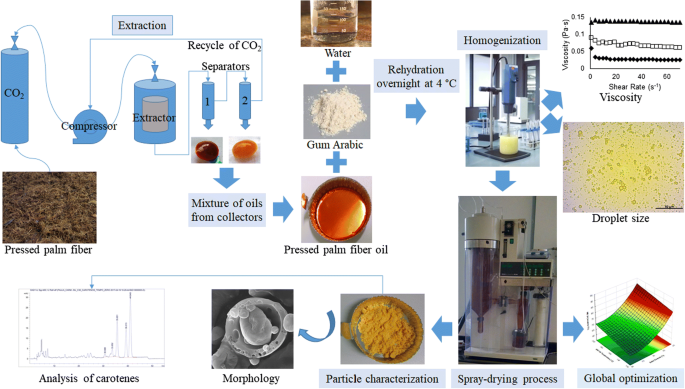

Effect Of Solids Content And Spray Drying Operating Conditions On The Carotenoids Microencapsulation From Pressed Palm Fiber Oil Extracted With Supercritical Co2 Springerlink

Spray Dryer An Overview Sciencedirect Topics

How Does Spray Dryer Work Lab Instrument Manufacturer

Schematic Diagram Of A Spray Dry Encapsulation Process And Image Of A Download Scientific Diagram

Spray Dryer Operating Principles Process Layout Uses Advantag

5 10 Psychrometric Charts And Spray Drying Project1 1 0 Documentation

Spray Dryer An Overview Sciencedirect Topics

What Is Spray Drying Frontiers In Spray Drying

Continuous Dryers Pharmaceutical Engineering

Spray Dryer Chamber Design How Is The Diameter Of The Evaporator Chamber Calculated

Spray Dryer An Overview Sciencedirect Topics

Schematic Diagram Of Spray Dryer 14 Download Scientific Diagram

Effect Of Spray Drying Temperature On Physicochemical Antioxidant And Antimicrobial Properties Of Pectin Sodium Alginate Microencapsulated Carvacrol Sciencedirect

Comments

Post a Comment